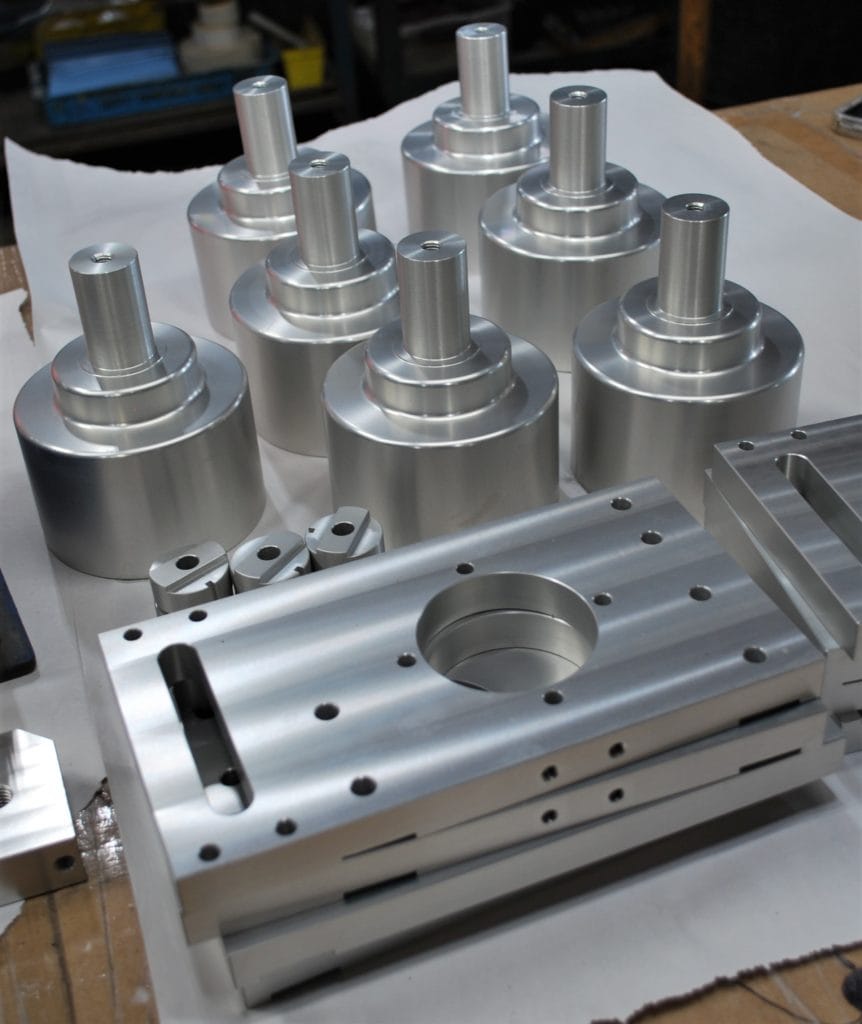

TMF offers low-to high-volume hard coat anodizing. Hard anodizing is not to be confused with Type II sulfuric acid anodizing. In which a very thin coating of aluminum oxide is deposited on the surface of the metal. Hard anodizing requires a special process, which produces a dense layer of aluminum oxide both on and in the aluminum surface. The thickness of this coating typically ranges from 1 to 3 mils.

Hard Coat anodize is thicker, harder and much more abrasion resistant that Type II sulfuric acid anodize. With type III anodize, half of the coating thickness penetrates into the surface of the aluminum while the other half builds up on the surface.

Any hard anodized surface has a high degree of lubricity. Impregnated with lubricants such as PTFE (Teflon) hard anodized aluminum surfaces have an even lower coefficient of friction.

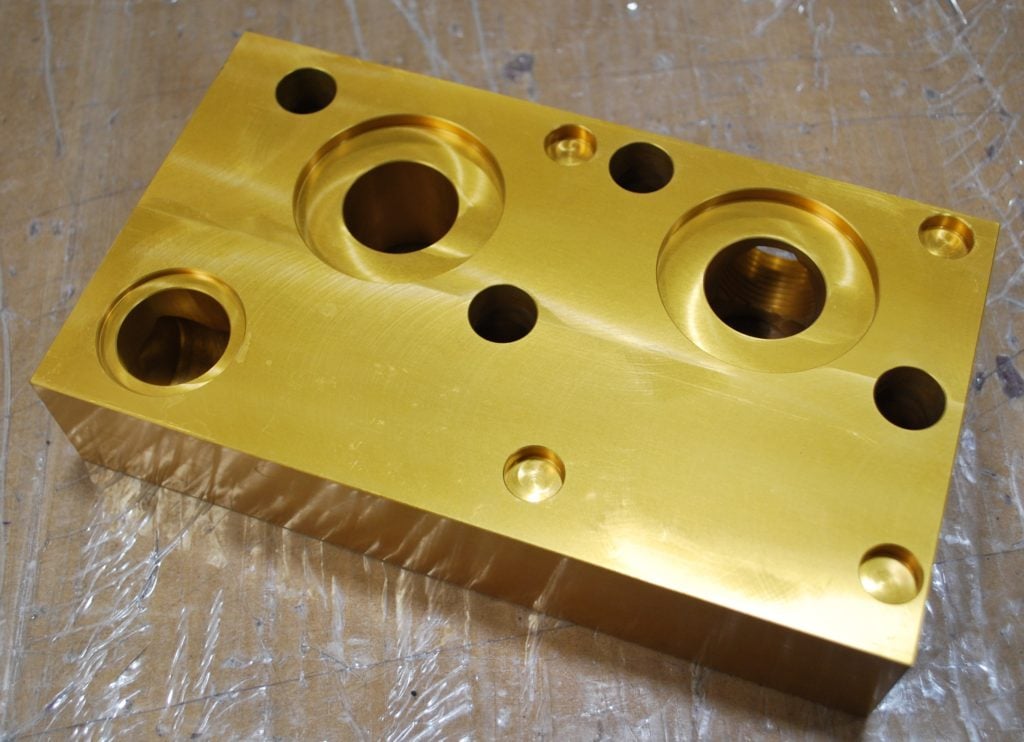

TMF can offer hard coat anodizing in clear, black, red, blue, and gold. When ordering hard anodizing from TMF, we need to be aware of the following information:

- Alloy of the aluminum

- Coating thickness

- Masking requirements (if any)

- Racking instructions (if possible)

At TMF we offer Hard Coat Anodizing to:

- MIL-PRF-8625/MIL-A-8625 Type III- Hard Coat Anodize

- Class I- Clear

- Class II- Color (Black, Yellow/Gold, Red, & Blue)

Certificates of compliance are provided upon request.