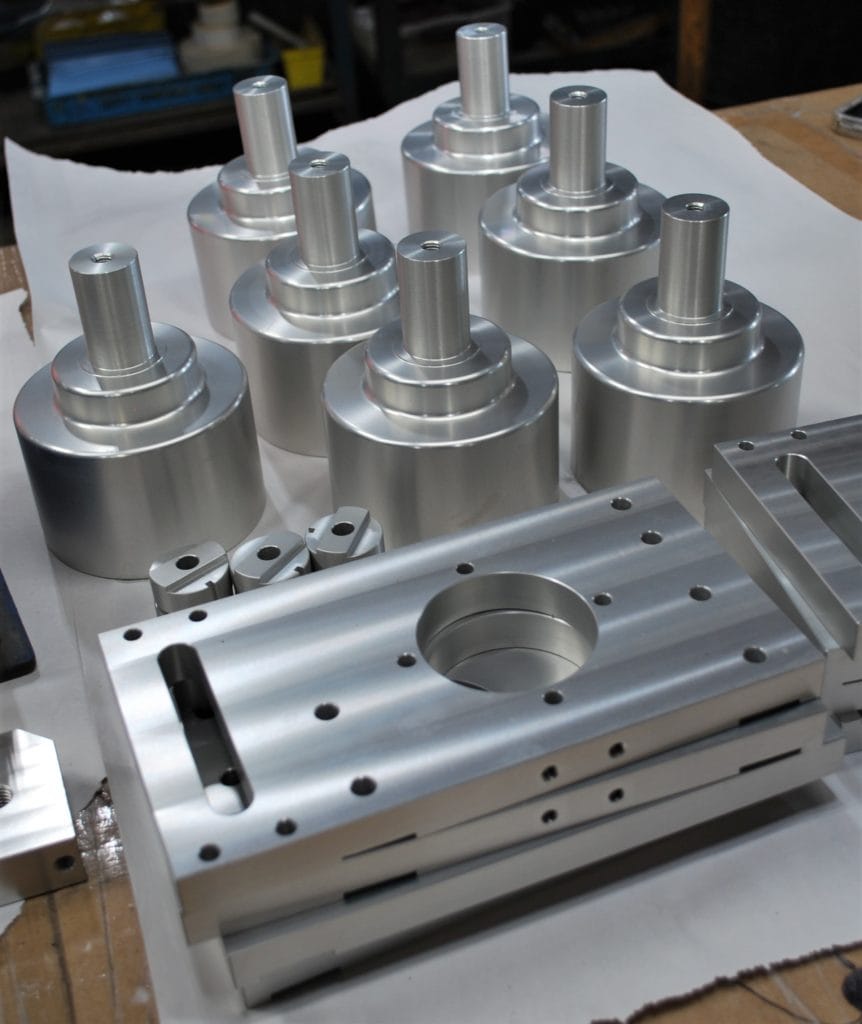

TMF offers mid- to high-volume sulfuric acid anodizing in lengths up to 9 ½ ft. long. This is the conventional, most widely used form of anodizing in use today. Anodizing is not a plating process. It is a complex series of steps involving pre-cleaning, etching, deoxidizing, anodizing, dying and sealing with careful rinsing after each immersion.

The overall thickness of the coating formed is a percentage penetrated in the substrate and a percentage of growth over the original dimension of the part.

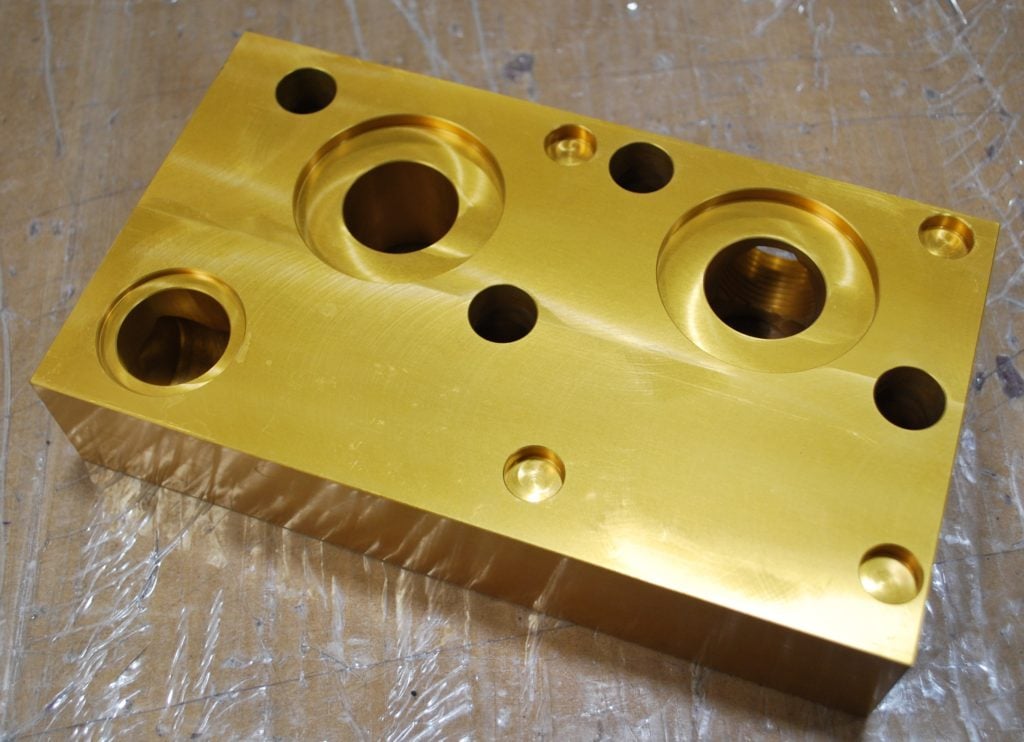

This anodizing process ranges from .0001”-.001” thick and is available in a wide range of colors.

We offer clear, black, gold, blue and red. We can achieve both a glossy and very matte appearance on all colors offered. Our finish is a perfect fit where abrasion resistance is required.

Our quality comes from establishing the exact standards of immersion times, solution temperatures, chemical concentrations and electrical conditions.

When ordering anodizing from TMF, we need to be aware of the following information:

- Alloy of the aluminum

- Coating thickness

- Masking requirements (if any)

- Racking instructions (if possible)

At TMF we offer Anodize to:

- MIL-PRF-8625/MIL-A-8625 Type II- Regular Anodize

- Class I- Clear

- Class II- Color (Black, Yellow/Gold, Red, & Blue)

Certificates of compliance are provided upon request.